Modern solid carbide drills produce holes in a tolerance zone of H8-H10; in which case the hole axis is accurate in half this tolerance. For eg:- A dia 10 hole drilled hole is between 22-45 microns which means the axis is controlled within 11-22 microns.

Reamed holes are accurate having a tolerance of H6-H7 i.e. for dia 10 :-11 to 16 microns, so it is obvious that to produce such an accurate hole , the hole axis has to be more accurate than 11-22 microns which is possible with a modern solid carbide drill, hence for such accurate holes it is a preferred process to Hole-mill & then Ream.

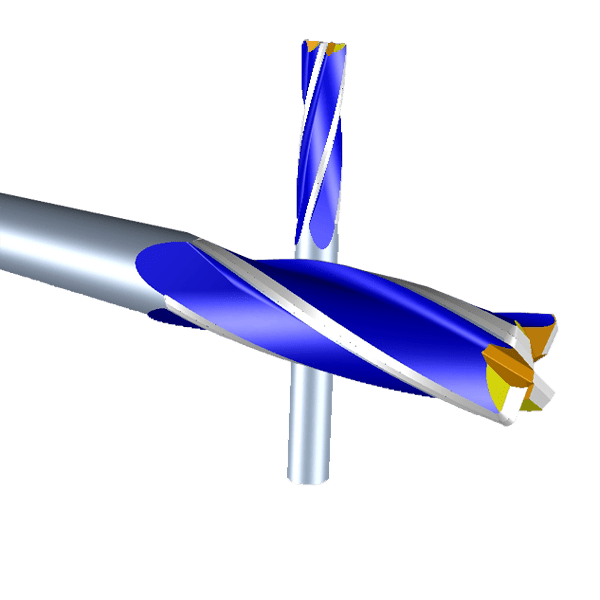

A Hole-mill is normally an undersized reamer with a boring geometry i.e. the size of the hole-mill is normally 0.2-0.6mm more than the size of the drill so that there are no drill marks on the hole plus the hole axis is corrected for subsequent reaming operation.

The stock for reaming is different for each type of material.

Steel & CI 0.3-0.4 mm

Aluminium 0.5-0.6 mm

Titanium 0.2-0.3 mm

Aayudh Hole-mills are optimised for geometry based on the materials to be hole-milled and are generally straight fluted.