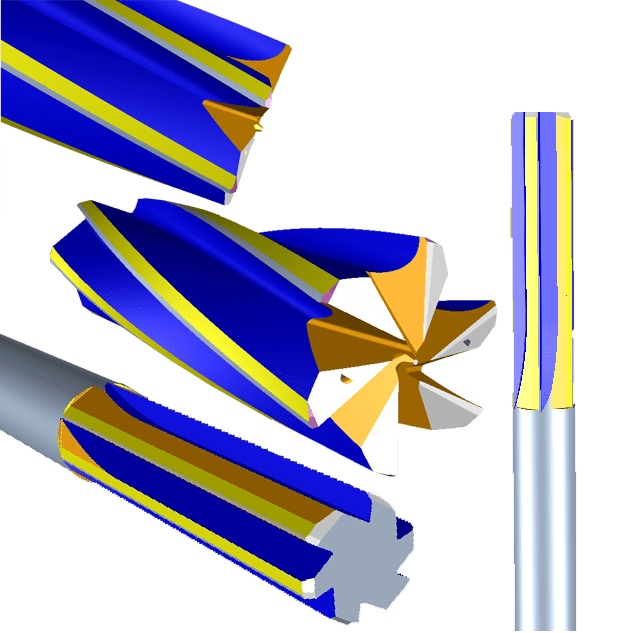

Reamers are the most used tools for finishing of holes from H6-H7 tolerances.The most widely used reamers in the diameter range 3-20 mm are manufactured in solid carbide. They work with reduced stock removal and therefore can withstand higher feed rates, compared to a drill with three flutes.

Solid carbide reamers offer enhanced hole quality due to internal coolant, special cutting edge geometry and variable pitch indexing of the flutes.

Benefits of Aayudh SC reamers:-

- excellent surface finish on the component (0.3-0.8 μCLA -depending on the application conditions like internal coolant, tool holding , fixturing ,etc)

- uniform concentricity for long tool life and dimensional accuracy.

- Internal coolant to better chip evacuation and reduced wear on the reamer.

- good circularity of the hole due to optimized pitching of the flutes.

- Aayudh makes reamers for optimized machining for through and blind holes.

Through holes :- For through holes we provide reamers with a small L .H. helix to push the chips forward to prevent erosion in the flutes or damage to the hole finish. In applications where there are fixturing limitation at the bottom of the hole to accomodate the chips which are pushed forward, we offer these reamers with straight flute. The corner chamfer angle guides the entry of the reamer in the hole and is critical to the performance of the reamer.Generally, the included angle is 90 º, but experience shows that chamfers with included angle 60 º give a much better entry in difficult to machine materials in stainless steel etc.

Blind holes:- For blind holes we offer straight flute reamers with a chamfer angle of 120º included and the chips are removed through the flutes.

Straight fluted reamers for blind holes will have only a central coolant hole to push the chips out through the flutes, but a straight fluted reamer for through holes will have the central coolant duct plugged and suitable holes will be made in the flutes to push the chips out.

The dimension of the chamfer on the reamer is dependent on the stock that is kept for the reamer.

Reamers follow the axis of the hole machined previously and cannot correct the axis of the hole. Hence it is important that the pre-hole has the right axis for the reamer, so there is a hole mill to correct the axis of the drilled hole prior to reaming.