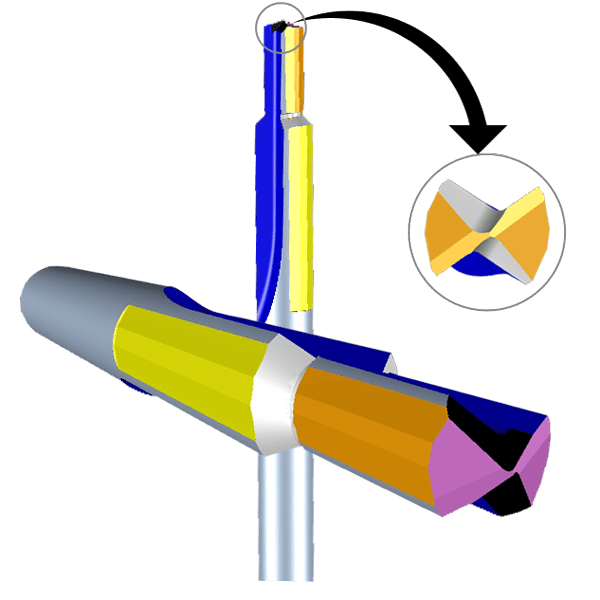

Hole making in aluminium is continuously expanding especially in the two-wheeler and car industry as more and more components are getting converted to aluminium. The characteristics of these holes are similar to those being machined by conventional step drill. However conventional step drill may not machine efficiently on holes which have a draft, due to which the cuts partly in the core and then in solid in the same hole; due to this a step burnishing drill with two guide pads ensures proper entry in the core portion and efficient cutting in the solid portion.

A burnish drill produces a hole from H8 to H9. The front geometry of a burnish drill ensures a built up edge free entry into the hole.