More than 60-65% of holes in the metal cutting industry have a chamfer at the start. Conventionally, drilling and chamfering have been two separate operations in hole-making.

For increasing productivity on machining centres, there is a trend to combine operations on the same axis for hole making. Typical examples are tap holes, rivet holes , etc. Step drills are mainly used for countersinking and counterboring operations.

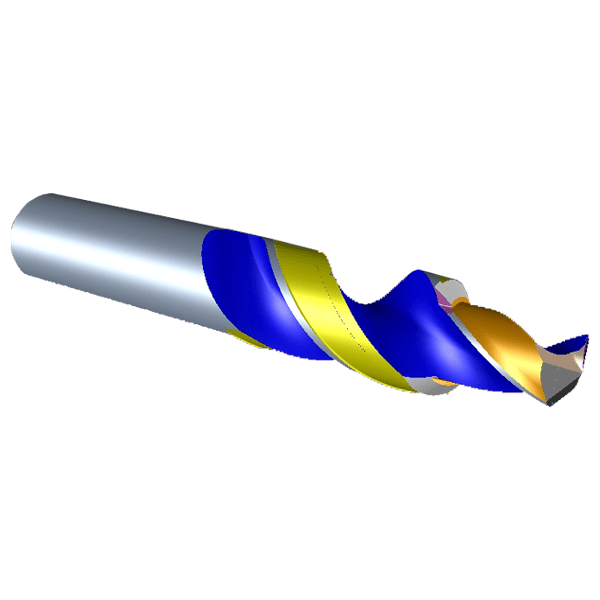

Aayudh uniquely optimizes the design of the Step Drill by providing Aayudh P & K, Aayudh M & S, Aayudh N etc, geometries and coatings based on the material being step drilled(for details refer drill page); this enables the user to have more regrinds, higher tool security at elevated parameters. (refer downloads)

However, it is important to consider the ratio of the step diameters and pilot diameters; generally the smaller diameter should not be less than 50% of the larger diameter, in order to get optimum efficiency in step drilling. Similarly , it is important to maintain the L/D ratio of the smaller drill diameter within 3-3.5 to maintain the right rigidity and stability in operation.