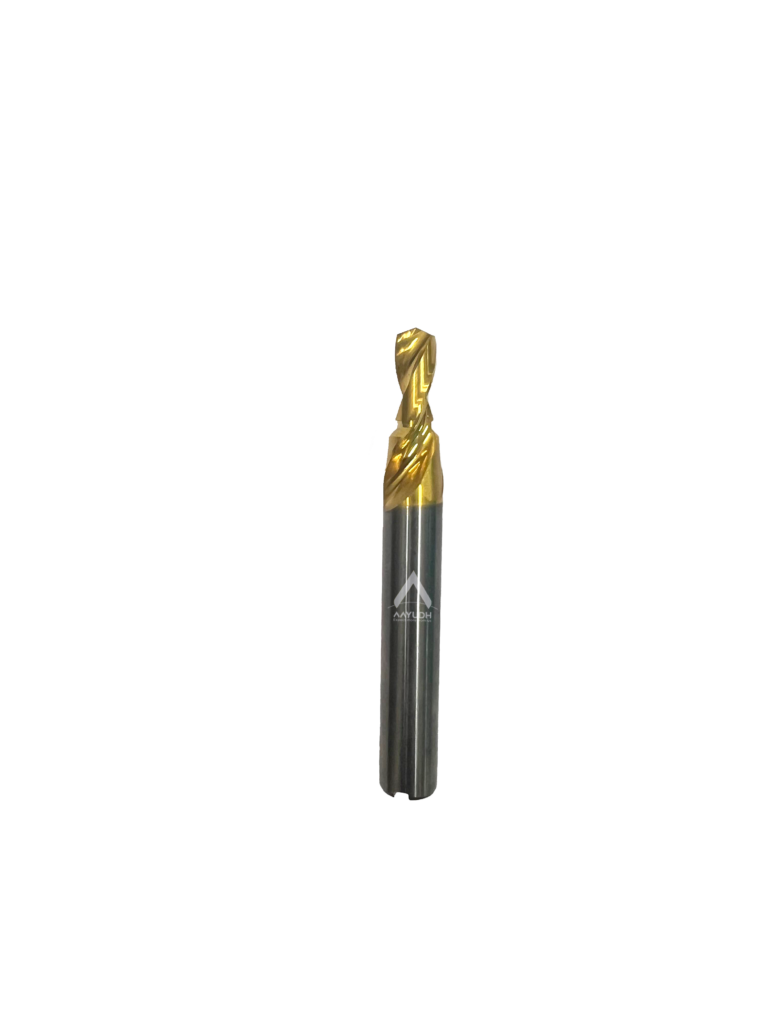

A Burnish Drill is a drill with two cutting edges and two burnishing pads for drilling in aluminium accurately(hole tolerance H8-H9) with a good surface finish(1.6Ra)

Because of the burnishing pads which act as guide, the burnish drill has a rubbing action in drilling. Consequently, this is recommended at lower cutting speeds like 60-80 m/min; today these drills are mostly used on drilling SPMs.

On modern machining centres, the burnish drills with modified point geometry is also used for deeper holes >L/D 7 in aluminium. In such cases , they are also called Twin Lip Gun Drills.

Most of the holes in aluminium components have a draught , due to which the drill cuts partly in the core and then in solid in the same hole, a burnish drill because of the two guide pads ensures a proper entry into the core portion of the hole and efficient cutting in the solid portion. A burnish drill produces a hole from H8 to H9. The front geometry of a burnish drill ensures a built up edge free entry into the hole.

Aayudh customizes the burnish drill for flat bottom holes also up-to L/D 3.

Hole making in aluminium is both easy and very difficult because of built up edge tendency. It is a more efficient strategy to machine the hole in a single pass and make it ready for PCD reaming.

On modern machining centres with high pressure coolant holes the burnishing drill L/D more than 5 up to 8-10.

©2025. Aayudh Tools. All Rights Reserved.